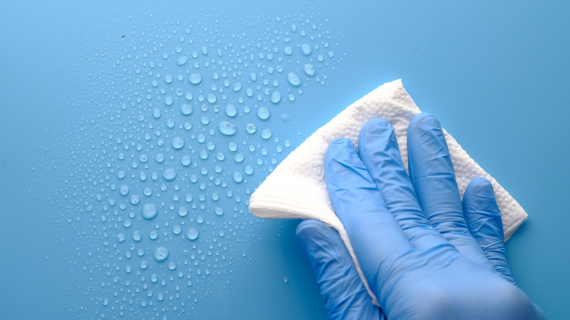

Product Features

Benefits of Using Cleanroom Dry Wipes:

![]() Contamination Control

Contamination Control

![]() Lint-Free

Lint-Free

![]() Durability

Durability

![]() Compatibility

Compatibility